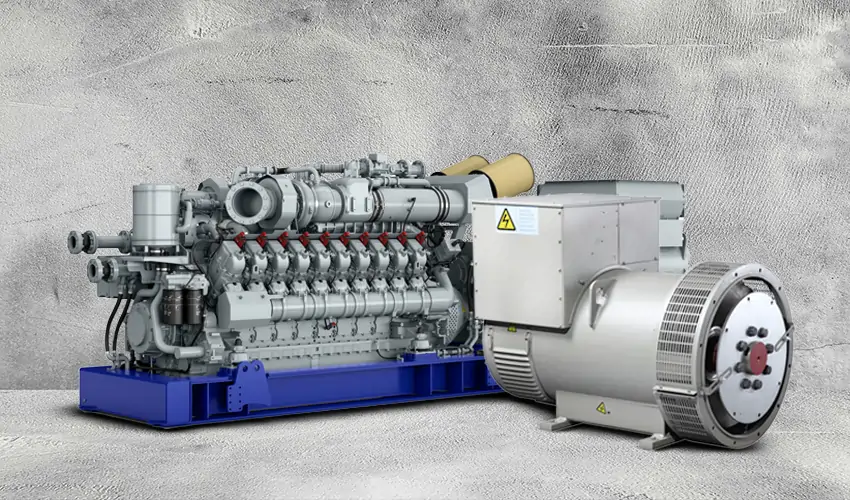

Choosing the right alternator for industrial use is critical. It can have a significant impact on your operations. An alternator converts mechanical energy into electrical power. It is a must in machinery, generators, and industrial systems. Proper selection ensures your equipment operates with high efficiency, dependability, and low cost. With many options, it’s vital to know your application’s needs. This includes its power and environmental requirements. A trusted alternator supplier, provides quality products and expert advice. They can help you choose the best option for your industrial needs. Making an informed decision now will pay off in the long run.

What is an alternator?

An alternator generates electricity by converting mechanical energy. It has extensive applications in industry, including generators, motors, and other machines. Understanding how it works is crucial for making the right choice.

Importance of Choosing the Right Alternator:

Choosing the right alternator affects the efficiency, reliability, and cost of your operations. An incorrect choice can cause frequent breakdowns, high maintenance costs, and lost productivity. Here are some key reasons why proper selection is vital:

Power Supply:

The alternator must match the power needs of your equipment. If it’s underpowered, it can cause failures. If it’s overpowered, it can waste energy.

Operational Efficiency:

A suitable alternator improves efficiency, leading to lower operational costs. This means saving money in the long run.

A good alternator boosts your operations’ reliability. It cuts downtime and disruptions.

Factors to Consider When Choosing an Alternator:

When selecting an alternator, consider the following factors:

Power Requirements:

Determine the total wattage needed for your equipment. Calculate the largest load to ensure the alternator can handle it. If you’re unsure, consult with an expert to avoid future issues.

Type of alternator:

There are different types of alternators, including:

- Synchronous alternators:

- These maintain a constant speed and output frequency. They are ideal for applications requiring stable power.

- Asynchronous alternators:

- These are simpler and usually less expensive. They are suitable for applications with varying loads.

Choose the type that best fits your specific application.

Environment:

Consider where you will use the alternator. Harsh conditions like dust, moisture, or extreme temperatures can affect performance. Look for alternators designed to handle these environments.

Efficiency:

Higher efficiency means more power for less fuel or energy. When comparing models, look for those that offer better efficiency ratings. This helps lower operational costs.

Maintenance Needs:

Some alternators need regular maintenance, while others are low-maintenance. Consider how much time and resources you can dedicate to upkeep. Opt for a model that balances performance and maintenance ease.

Size and Weight:

Check that the alternator fits and meets your weight limits. If space is tight, compact models may be necessary.

Understanding Specifications:

When looking at alternators, familiarize yourself with common specifications:

- Voltage: Make sure the alternator matches your equipment’s voltage requirements.

- Frequency: Check the frequency output. Industrial applications usually must be 50 Hz or 60 Hz.

- Phase: Check if you need a single-phase or three-phase alternator for your equipment.

Choosing the Right Supplier:

Finding a trustworthy alternator supplier is crucial. A good supplier will offer quality products, expert advice, and reliable support. Here are some tips for selecting the right supplier:

Reputation:

Research suppliers and read reviews. A reputable supplier will have positive feedback from previous customers.

Range of Products:

Choose a supplier that offers a variety of alternators to suit different needs. This ensures you can find the right fit for your application.

Customer Support:

Reliable customer support is essential. Look for suppliers who provide guidance during and after the purchase.

Warranty and After-Sales Service:

Check if the supplier offers warranties and after-sales services. This can save you money on repairs and replacements in the long run.

Why Choose Unitech Motor?

Unitech Motor stands out as a leading alternator supplier for industrial applications. Here’s why:

Quality Products:

Unitech Motor provides high-quality alternators designed for various industrial needs. Their products meet international standards, ensuring reliability and efficiency.

Expert Advice:

The team at Unitech Motor has extensive knowledge about alternators. They can help you select the right model based on your specific requirements.

Comprehensive Range:

Unitech Motor has a wide range of alternators. You will find the perfect fit for your application. Whether you need a small unit or a heavy-duty model, it has many options.

Customer Satisfaction:

Unitech Motor prioritizes customer satisfaction. They provide excellent support and services to ensure you have a positive experience.

Conclusion:

Choosing the right alternator for industrial use is vital. It ensures efficient, reliable operations. By considering power needs, type, environment, and efficiency, you can decide well.

Partnering with a trustworthy alternator supplier like Unitech Motor can simplify the process. With quality products and expert help, you can find the perfect alternator for your needs.

Remember, making the right choice now can save you time and money in the future. Seek help from experts to ensure your operations function without issues.

Leave a Reply