In the industrial sector, the demand for reliable, efficient, and safe electrical systems is paramount. Industrial facilities often operate under challenging conditions, including extreme temperatures, moisture, dust, and exposure to chemicals. These environments require robust solutions that can withstand harsh conditions while ensuring uninterrupted power distribution. This is where customized distribution boxes come into play. Tailored to meet the specific needs of industrial applications, these boxes offer unparalleled flexibility, durability, and performance. In this ultimate guide, we’ll explore everything you need to know about customized distribution boxes for industrial use and why Eabel is the trusted partner for these essential solutions.

What Are Customized Distribution Boxes?

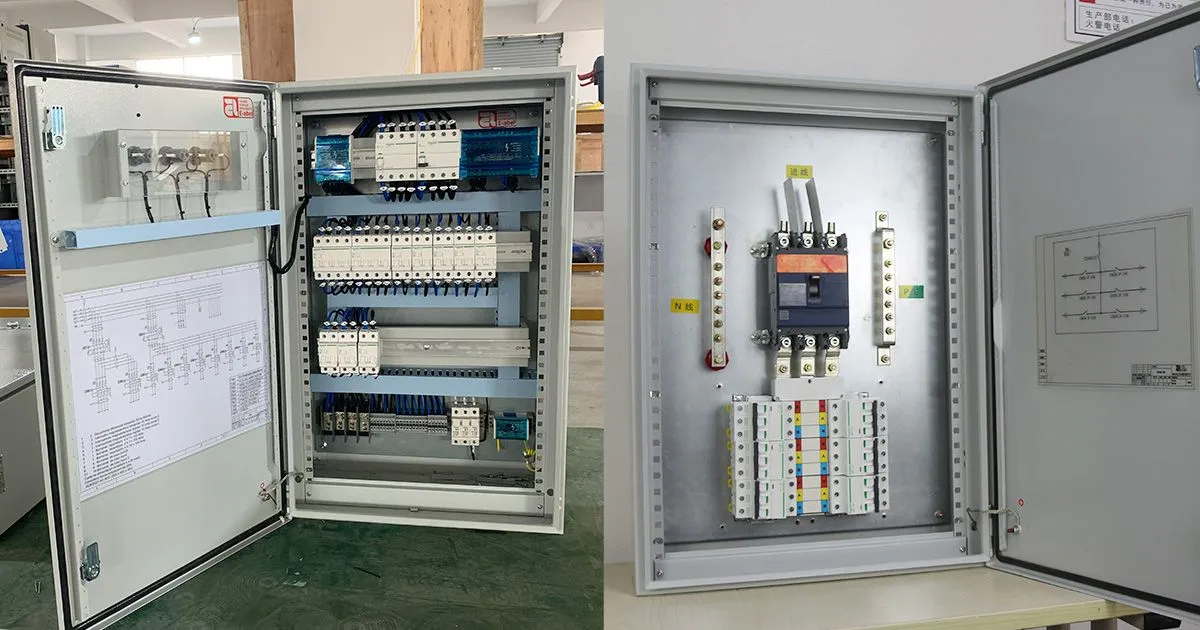

Customized distribution boxes are specialized Custom Enclosures designed to house and protect electrical components such as circuit breakers, fuses, and switches. Unlike standard distribution boxes, which come in fixed sizes and configurations, customized boxes are built to meet the unique requirements of a project. This includes considerations such as size, material, layout, and additional features like weatherproofing, explosion-proofing, or enhanced security measures. For industrial applications, customization ensures that the distribution box can handle the specific challenges of the environment while maintaining optimal performance.

Why Industrial Facilities Need Customized Distribution Boxes

Industrial facilities have unique electrical needs that standard distribution boxes often cannot meet. Here are some reasons why customized distribution boxes are essential for industrial use:

1. Harsh Environmental Conditions

Industrial environments are often exposed to extreme conditions, such as high temperatures, moisture, dust, and corrosive chemicals. Customized distribution boxes can be designed with materials and features that withstand these challenges, ensuring reliable performance even in the most demanding settings.

2. High Power Demands

Industrial facilities typically require high-capacity electrical systems to power heavy machinery and equipment. Customized distribution boxes can be designed to handle higher voltage and current levels, ensuring safe and efficient power distribution.

3. Space Constraints

Industrial facilities often have limited space for electrical installations. Customized distribution boxes can be designed to fit into tight or unconventional spaces, optimizing the use of available area without compromising functionality.

4. Safety and Compliance

Industrial facilities must adhere to strict safety standards and regulations. Customized distribution boxes can be designed to meet these requirements, incorporating features like lockable doors, tamper-proof designs, and integrated grounding systems to enhance safety.

Key Features of Customized Distribution Boxes for Industrial Use

When designing a customized distribution box for industrial applications, several key features should be considered to ensure optimal performance and safety:

1. Durable Materials

Industrial-grade distribution boxes are typically made from robust materials such as stainless steel, aluminum, or reinforced plastics. These materials offer excellent resistance to corrosion, impact, and extreme temperatures, ensuring long-lasting performance.

2. Weatherproofing and Sealing

For outdoor or harsh environments, weatherproofing is essential. Customized distribution boxes can be designed with gaskets, seals, and coatings to prevent moisture, dust, and debris from entering the enclosure.

3. Explosion-Proofing

In hazardous environments where flammable gases or dust may be present, explosion-proof distribution boxes are a must. These boxes are designed to contain any internal explosions, preventing them from igniting the surrounding atmosphere.

4. Modular Design

A modular design allows for easy upgrades and modifications as your electrical needs evolve. Customized distribution boxes can be designed with removable panels, additional compartments, and scalable layouts to accommodate future changes.

5. Advanced Cooling Systems

Industrial facilities often generate significant heat, which can affect the performance of electrical components. Customized distribution boxes can include advanced cooling systems, such as fans, vents, or heat sinks, to maintain optimal operating temperatures.

Applications of Customized Distribution Boxes in Industrial Settings

Customized distribution boxes are used in a wide range of industrial applications. Here are some examples:

1. Manufacturing Plants

Manufacturing plants rely on heavy machinery and equipment that require high-capacity electrical systems. Customized distribution boxes ensure safe and efficient power distribution, minimizing downtime and maximizing productivity.

2. Oil and Gas Facilities

Oil and gas facilities operate in hazardous environments where safety is critical. Explosion-proof and corrosion-resistant distribution boxes are essential for ensuring reliable power distribution in these settings.

3. Chemical Processing Plants

Chemical processing plants often deal with corrosive substances that can damage standard electrical components. Customized distribution boxes made from corrosion-resistant materials ensure long-lasting performance in these challenging environments.

4. Power Generation Facilities

Power generation facilities require robust electrical systems to handle high voltage and current levels. Customized distribution boxes can be designed to meet these demands, ensuring safe and efficient power distribution.

Why Choose Eabel for Customized Distribution Boxes?

When it comes to customized distribution boxes for industrial use, Eabel stands out as a trusted and reliable provider. With years of experience and a commitment to quality, Eabel offers a wide range of customization options to meet your specific needs. Here are some reasons why you should choose Eabel for your customized distribution boxes:

1. Expertise and Experience

Eabel has a team of skilled professionals who specialize in designing and manufacturing customized distribution boxes for industrial applications. Their expertise ensures that you receive a product that meets the highest standards of quality and performance.

2. Wide Range of Options

At Eabel, you can choose from a variety of materials, sizes, and configurations to create a distribution box that is perfectly suited to your requirements. Whether you need a compact box for a tight space or a large, rugged enclosure for a harsh environment, Eabel has you covered.

3. Advanced Manufacturing Techniques

Eabel uses state-of-the-art manufacturing techniques to ensure that every distribution box is built to last. From precision cutting and welding to advanced finishing processes, their manufacturing methods guarantee durability and reliability.

4. Customer-Centric Approach

At Eabel, customer satisfaction is a top priority. Their team works closely with you to understand your needs and provide personalized solutions that exceed your expectations. From initial consultation to final delivery, Eabel is committed to delivering a seamless experience.

5. Competitive Pricing

Despite offering high-quality customized solutions, Eabel maintains competitive pricing to ensure that you get the best value for your investment. Their transparent pricing model means no hidden costs or surprises.

Conclusion

Customized distribution boxes are an essential component of industrial electrical systems, offering unmatched flexibility, safety, and efficiency. Whether you’re working in a manufacturing plant, oil and gas facility, or chemical processing plant, a customized solution can ensure that your electrical needs are met with precision and reliability. For the best in customized distribution boxes, look no further than Eabel. With their expertise, wide range of options, and customer-centric approach, Eabel is your trusted partner for all your industrial electrical distribution needs. Explore their offerings today and discover how customized distribution boxes can transform your industrial operations.

Leave a Reply