What are Tumble Printing Machines?

Tumble printing machines are special machines that print words, images, and designs. They can print on different materials like plastics, metals, and paper. They use a tumbling action to rotate the material while printing, moving it in a circular motion to print. This makes them great for printing large quantities. ONCE TECH tumbler printing machine is useful in many industries. They help label water bottles, print on food containers, and create packaging materials. They offer fast and precise printing, making them an essential asset for businesses that need high-quality prints at a rapid pace.

Benefits in Large-Scale Manufacturing

Tumble printing machines are a game-changer in large-scale manufacturing. They offer many benefits, including:

Print Faster: Print at high speeds, producing more products in less time.

Consistent Quality: Reduce errors and defects, ensuring uniform prints every time.

Save Money: Lower costs per unit, making production more cost-effective.

Additionally, tumble-printing machines include:

Increase Productivity: Automate printing processes, freeing up staff for other tasks.

Improve Efficiency: Streamline production, reducing waste and saving resources.

Enhance Customization: Allow for personalized prints, making products more unique.

Support High-Volume Production: These machines handle large quantities with ease. This makes them ideal for mass production.

Tumble printing machines improve production and product quality. They also reduce costs. This leads to increased customer satisfaction, loyalty, and business growth.

How to Use Tumble Printing Machines

Using tumble printing machines is straightforward. Follow these steps to get started:

1. Check Your Needs:

– Determine the materials you want to print on (plastics, metals, paper, etc.)

– Decide on the printing speed you need (high speed, low speed, etc.)

– Consider the size and shape of your materials

2. Choose the Right Machine:

– Select a machine that matches your material and speed needs

– Consider your budget and choose a machine that fits within it

– Research different models and read reviews to find the best fit

3. Install and Set Up:

– Follow the manufacturer’s instructions for installation

– Connect the machine to a power source and any necessary software

– Perform any necessary calibration or testing

4. Train Your Team:

– Provide complete training on machine operation and maintenance

– Ensure team members understand safety protocols and procedures

– Offer ongoing support and troubleshooting help

Extra Tips:

– Often Maintain Your Machine:

Clean and lubricate the machine often to ensure optimal performance.

– Use High-Quality Ink and Supplies:

Choose ink and supplies that are compatible with your machine and materials.

– Watch Print Quality:

Often check print quality and adjust settings as needed.

Following these steps and tips helps you use tumble printing machines. This streamlines your printing process and improves productivity.

Common Uses

Tumble printing machines are used in the following ways:

Packaging

Tumble printers are used in packaging to print on various materials. They can print on plastics, metals, paper, and more. This includes printing on water bottles, food containers, cans, foil wrappers, boxes, and bags. Custom packaging designs and labels can also be created using these machines.

Labeling

Tumble printing machines print labels for many products. These products include food, cosmetics, and pharmaceuticals. They can also create labels with variable data like barcodes and serial numbers. Additionally, labels can be printed in different shapes, sizes, and materials to suit specific needs.

Security Printing

Security printing is another important application of tumble printing machines. Tumble printing machines print secure documents. They add advanced security features like watermarks and holograms. These machines can print sensitive information with high levels of precision and accuracy.

Other Applications

Tumble printing machines also print promotional materials. They’re used in medical settings to print on devices and supplies. Tumble printing machines are flexible and versatile. They are valuable in many different industries.

Maintenance and Troubleshooting

Regular Cleaning

The tumble printing machine needs regular cleaning, which is essential to prevent clogging and damage to your tumble printing machine. Regular cleaning of the machine is essential to maintaining its performance. Be sure to clean the print heads, ink systems, and rollers to prevent clogs and damage. Use a soft cloth and gentle cleaning solutions to avoid damaging the machine’s components. Regular cleaning helps prevent problems like clogged print heads and damaged rollers. This helps avoid downtime and costly repairs.

Checking Performance

Check your tumble printing machine’s performance to ensure it’s working. Check the print quality, ink levels, and machine settings. Adjust the settings as needed to maintain high-quality prints. Regular checks help find small issues before they become big problems. This helps you avoid surprises and keep the machine running.

Fixing Issues

Notice any issues? Fix them promptly to prevent complications. Quick repairs mean less downtime. Common issues include clogged print heads, paper jams, and ink leaks. Fixing these issues will help prevent further damage to the machine. This swift action will also reduce downtime, minimizing the impact on productivity. Keep a maintenance kit on hand that includes replacement parts and cleaning supplies to help you fix issues.

Extra Tips:

– Schedule regular maintenance checks to ensure the machine is running.

– Keep a record of maintenance and repairs to track the machine’s history.

– Train your team on basic maintenance and troubleshooting procedures.

If you need clarification on maintenance or troubleshooting, check the user manual. If you still need help, contact the manufacturer’s support team.

Types of printing machines:

Different types of printing machines are given below

1. Offset High-volume printing using metal plates to transfer ink onto paper.

2. Digital: Print-on-demand using toner or inkjet technology, ideal for small runs.

3. Screen: Pushing ink through a mesh screen to print designs onto various materials.

4. Inkjet: Dropping ink onto paper or other materials to create images.

5. Laser: Using a laser beam to produce high-quality text and images.

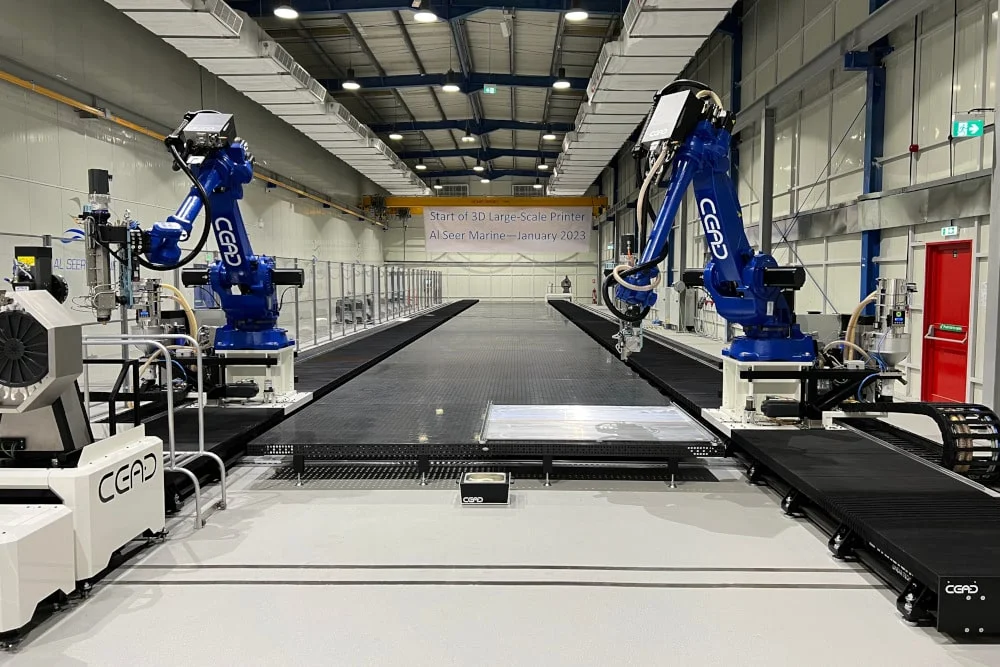

6. 3D: Creating three-dimensional objects layer by layer using various materials.

7. Flexographic: Printing on flexible materials like plastics using flexible plates.

8. Rotogravure: Engraved cylinders transfer ink onto paper or other materials.

9. Pad: Transferring ink from an etched plate onto small or irregularly shaped items.

10. Tumble: Printing on various materials, like plastics, metals, and paper, using a tumbling action.

Each type of printing machine has its unique features, advantages, and applications, allowing businesses to choose the best fit for their specific printing needs.

Conclusion

Tumble printing machines support large-scale manufacturing by increasing efficiency, consistency, and cost-effectiveness. Tumble printers print quickly, producing many prints in a short time. This helps businesses produce high-quality prints, meeting demand without sacrificing quality. The tumbling action ensures consistent prints every time. This is crucial in large-scale manufacturing, where quality control is essential. Tumble printers are cost-effective. They save resources and reduce waste. Regular cleaning and checks help tumble printers work their best.

Tumble printing machines offer various benefits, including versatility, customization, and precision. Tumble printers print on many materials. They’re used in various industries. Their high level of precision makes them ideal for printing sensitive information. Additionally, their accuracy ensures that the printed information is reliable and trustworthy. Understanding how tumble printers work helps businesses use them well. Following a simple guide helps maximize their potential. This leads to efficiency, consistency, and cost savings in large-scale manufacturing.

Leave a Reply