Imagine you’re a scientist working to develop new materials or a quality control engineer ensuring that a product meets industry standards. In these scenarios, understanding how materials respond to changes in temperature is crucial. Thermal analysis techniques provide the data needed to ensure materials perform as expected.

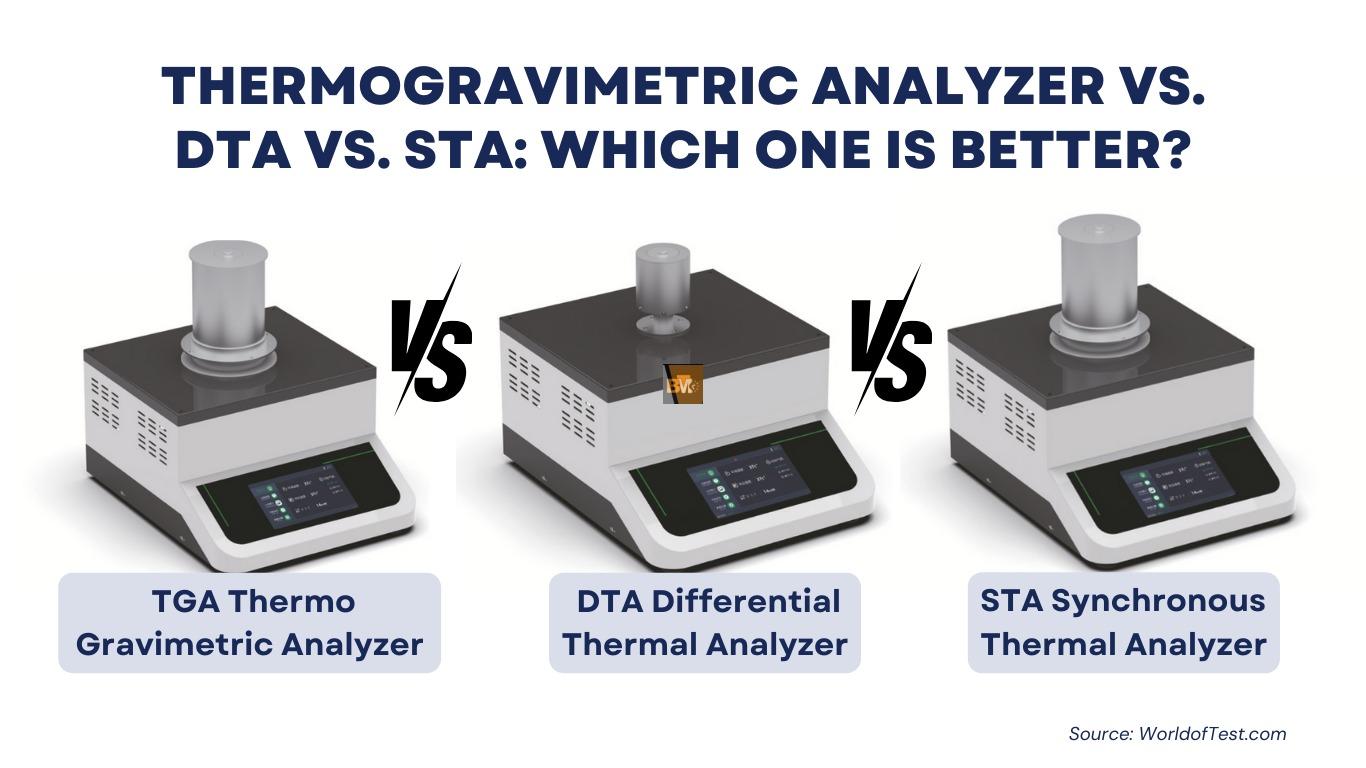

Among the various methods, three stand out: the Thermogravimetric Analyzer (TGA), the Differential Thermal Analyzer (DTA), and the Synchronous Thermal Analyzer (STA). In this blog post, we’ll compare these three powerful tools to help you determine which one is best for your needs.

What is Thermal Analysis?

Thermal analysis encompasses a variety of techniques used to measure how physical and chemical properties of materials change with temperature. It is widely used in industries such as pharmaceuticals, polymers, and materials science for quality control, research, and development. These techniques provide crucial insights into material properties like thermal stability, decomposition, phase transitions, and composition.

Thermogravimetric Analyzer (TGA)

The Thermogravimetric Analyzer, or TGA, has been a cornerstone in thermal analysis since its development in the mid-20th century. TGA measures changes in the mass of a sample as it is heated, cooled, or held at a constant temperature.

How a TGA Works

A TGA operates by heating a sample and continuously measuring its mass with a high-precision balance. The change in mass is recorded as a function of temperature or time. The main components of a TGA include:

- Balance: Measures the mass of the sample.

- Furnace: Controls the temperature around the sample.

- Sample Holder: Holds the sample in place during analysis.

Typical Applications of TGA

TGA is used to study:

- Decomposition: Determining the thermal stability and decomposition patterns of materials.

- Composition Analysis: Identifying the proportion of components in a mixture.

- Thermal Stability: Evaluating how materials withstand high temperatures.

Advantages of Using a TGA

- High Sensitivity: Capable of detecting very small changes in mass.

- Quantitative Data: Provides precise measurements that can be used to calculate decomposition rates and other properties.

Limitations of TGA

- Limited to Mass Change: Does not provide information on the nature of thermal events, only the mass change.

- Surface Requirements: Requires a smooth, clean sample surface for accurate measurements.

Differential Thermal Analyzer (DTA)

The Differential Thermal Analyzer, or DTA, was developed to provide insights into thermal events that do not involve mass changes. It measures temperature differences between a sample and an inert reference material.

How a DTA Works

In a DTA, both the sample and reference material are subjected to the same temperature program. The temperature difference between them is measured and recorded. Key components include:

- Sample Holder and Reference Holder: Holds the sample and reference material.

- Differential Thermocouples: Measure the temperature difference between the sample and reference.

Typical Applications of DTA

DTA is used to study:

- Phase Transitions: Identifying melting points, crystallization, and glass transitions.

- Thermal Events: Detecting endothermic (heat-absorbing) and exothermic (heat-releasing) reactions.

Advantages of Using a DTA

- Qualitative Data: Provides insights into the nature of thermal events.

- Versatility: Can be used with a wide range of materials.

Limitations of DTA

- No Mass Change Data: Does not provide quantitative information about mass changes.

- Sensitivity: Can be influenced by sample size and heating rate.

Synchronous Thermal Analyzer (STA)

The Synchronous Thermal Analyzer, or STA, combines the capabilities of TGA and DTA/DSC (Differential Scanning Calorimetry) in one instrument, allowing simultaneous measurement of mass changes and thermal events.

How an STA Works

An STA operates by simultaneously recording both the mass change and the heat flow in a sample as it is subjected to a temperature program. This dual measurement is achieved through integrated TGA and DTA/DSC sensors.

Typical Applications of STA

STA is used for:

- Comprehensive Thermal Analysis: Providing both mass change and thermal event data in a single experiment.

- Advanced Material Characterization: Offering detailed insights into material properties.

Advantages of Using an STA

- Efficiency: Simultaneous data collection saves time and reduces sample preparation.

- Comprehensive Data: Provides both quantitative and qualitative information.

Limitations of STA

- Higher Cost: More expensive than individual TGA or DTA instruments.

- Complex Data Interpretation: Requires expertise to analyze the combined data.

Comparing TGA, DTA, and STA

Measurement Capabilities

- TGA: Measures mass change as a function of temperature or time.

- DTA: Measures temperature differences between a sample and a reference material.

- STA: Measures both mass change and thermal events simultaneously.

Data Output

- TGA: Provides quantitative data on mass changes.

- DTA: Provides qualitative data on thermal events.

- STA: Provides both quantitative and qualitative data.

Applications and Suitability

- TGA: Ideal for decomposition and composition analysis.

- DTA: Best for phase transitions and identifying thermal events.

- STA: Suitable for comprehensive thermal analysis.

Situations for Each Analyzer

- TGA: Use when you need precise mass change data for decomposition studies or composition analysis.

- DTA: Choose for identifying phase transitions and thermal events without concern for mass change.

- STA: Opt for when both mass change and thermal event data are required in a single run.

Real-World Applications

Automotive Industry

In the automotive sector, TGA is used for studying the thermal stability of materials in engine components, while DTA helps in identifying the phase transitions of metals and alloys. STA is employed for comprehensive analysis of composite materials used in car bodies and interiors.

Pharmaceutical Industry

Pharmaceutical companies use TGA to analyze the decomposition patterns of active pharmaceutical ingredients, DTA to determine melting points of drugs, and STA for a detailed study of drug formulations and excipients.

Polymer Science

In polymer science, TGA is utilized to study the thermal degradation of polymers, DTA for analyzing phase transitions like melting and crystallization, and STA for a thorough understanding of polymer composites.

Choosing the Right Thermal Analyzer for Your Needs

When selecting a thermal analyzer, consider the following factors:

- Type of Data Required: Do you need mass change data, thermal event data, or both?

- Budget: TGA and DTA are generally more affordable than STA.

- Specific Applications: Match the analyzer to your material and analysis needs.

Choosing the right thermal analyzer depends on your specific needs and applications. TGA, DTA, and STA each offer unique advantages and cater to different aspects of thermal analysis. Understanding these differences can help you make an informed decision, ensuring accurate and reliable results for your materials.

For more information on thermal analyzers and to explore advanced testing technologies, visit WorldofTest.com.

Leave a Reply